A TPO (Thermoplastic Olefin) roof is a type of single-ply roofing membrane commonly used in commercial, industrial, and some residential buildings. It’s made from a blend of rubber, ethylene-propylene rubber, and fillers, typically reinforced with polyester or fiberglass. TPO roofs are known for their durability, energy efficiency, and ease of installation.

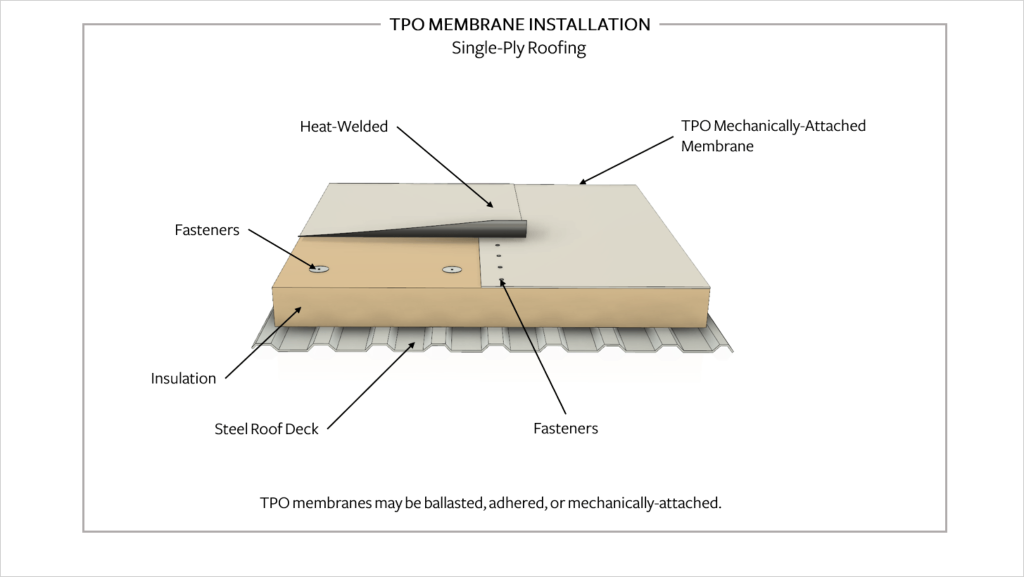

These roofs often come in white or light-colored surfaces, reflecting sunlight and heat away from the building, which can reduce cooling costs. They are installed in large, seamless sheets that are heat-welded together at the seams, creating a watertight barrier across the entire roof surface to minimize the risk of leaks.

TPO membranes are resistant to UV radiation, ozone, and chemical exposure, making them suitable for various climates and environments. They also resist mold, mildew, and algae growth. Additionally, TPO roofs are designed to accommodate the natural expansion and contraction of building materials, preventing cracking and splitting over time.

Overall, TPO roofs offer a cost-effective, reliable, and energy-efficient roofing solution for a wide range of buildings.