An EPDM (Ethylene Propylene Diene Monomer) roof is a synthetic rubber roofing membrane frequently applied in low-slope buildings, including commercial, industrial, and select residential structures. These roofs are esteemed for their durability, weather resistance, and straightforward installation process.

EPDM roofing membranes consist of a synthetic rubber compound comprising ethylene, propylene, and diene monomer. This formulation grants EPDM roofs remarkable flexibility, enabling them to expand and contract with temperature fluctuations without sustaining damage. This flexibility also allows the EPDM membrane to mold to the contours of the roof surface, creating a seamless and watertight seal.

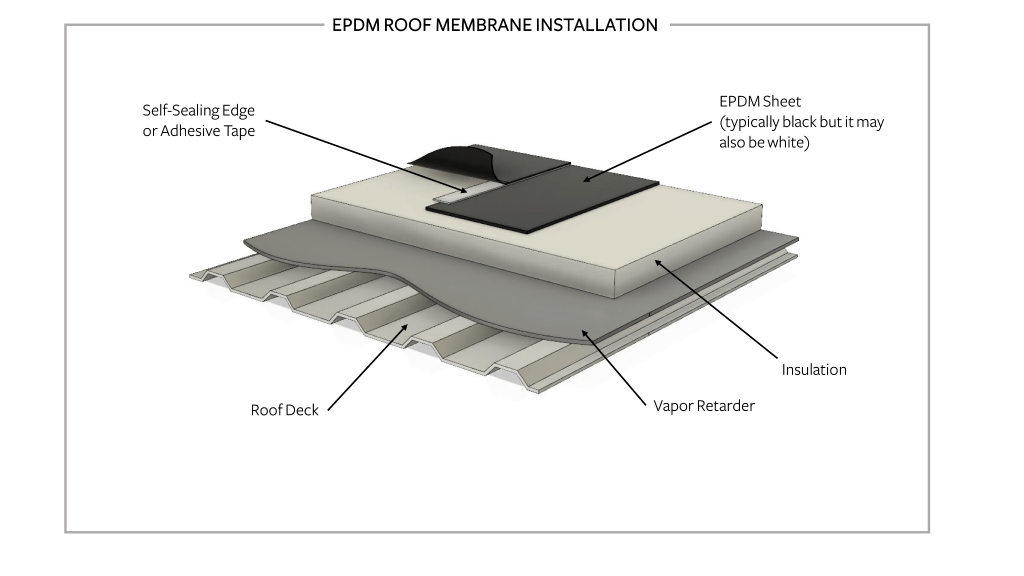

Typically, EPDM roofs are installed in large sheets using mechanical attachment, adhesive bonding, or ballasting with stones or pavers. Seams are sealed using specialized adhesives or tapes to prevent water infiltration.

EPDM roofing membranes demonstrate high resistance to UV radiation, ozone, and weathering, rendering them suitable for diverse climates and environmental conditions. They also withstand hail, wind, and thermal shock. With minimal maintenance, EPDM roofs can endure for 30 years or more.

In summary, EPDM roofs offer a dependable and cost-effective roofing solution for structures with low-slope or flat roof designs. Their durability, weather resilience, and ease of installation make them a preferred choice among property owners and construction professionals.